In the world of luxury watchmaking, accuracy is everything. A Rolex isn’t defined only by its aesthetics — its true value lies in the precision of the movement beating inside. Noob Factory, known for producing some of the finest super clone Rolex models, has long understood this philosophy. Behind every Daytona, Submariner, or GMT Master II lies a detailed, science-driven testing process designed to replicate the performance of genuine Rolex calibers.

This is how Noob Factory ensures every watch doesn’t just look authentic — it performs with the same stability, power reserve, and long-term reliability collectors expect.

Precision Starts at the Movement Bench

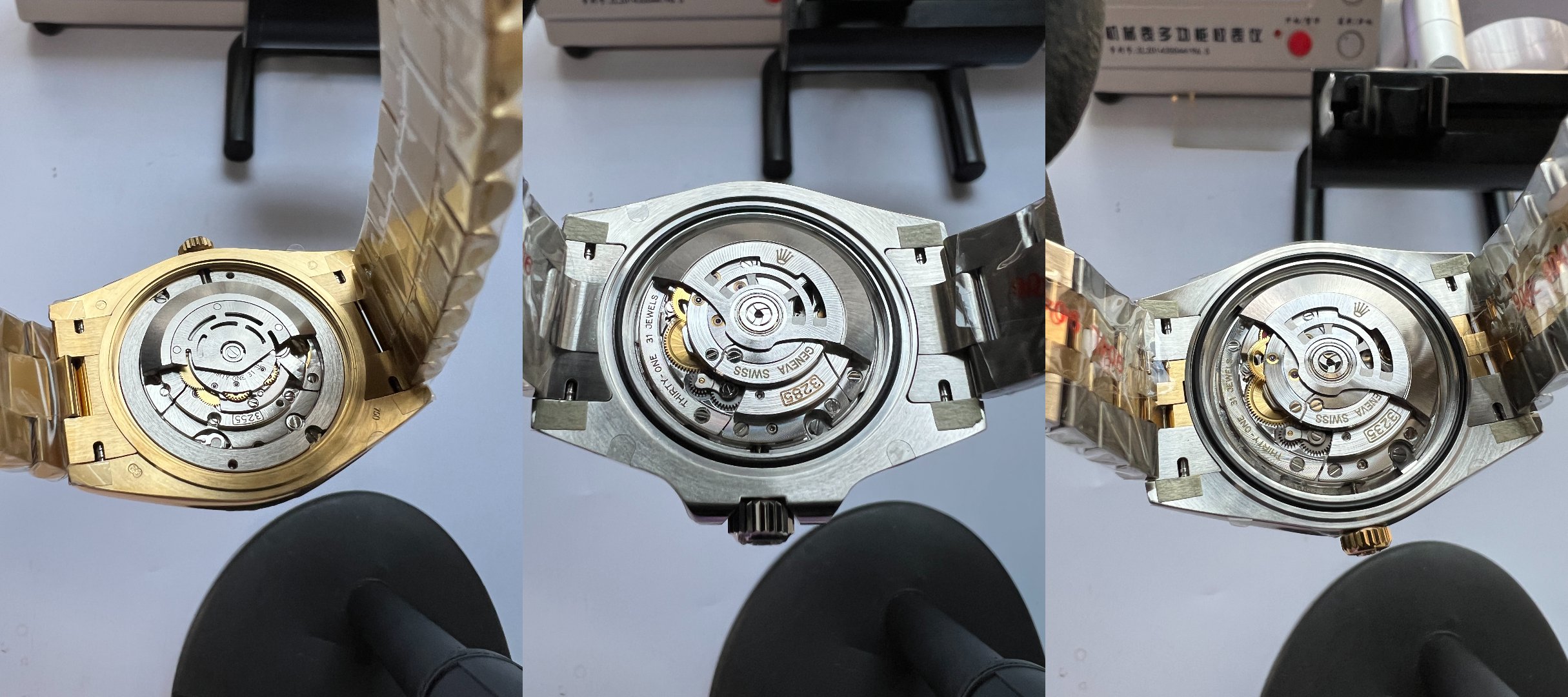

Noob’s movement testing begins before the watch is even assembled. Each clone 4130, 3235, and 3135 movement is inspected under magnification to ensure consistency in machining. Bridges, rotors, and jewels must align perfectly — one misplaced tolerance can alter amplitude, friction, or power transmission.

Every movement passes through:

- Visual inspection under 10x and 20x loupes

- Rotor-bearing lubrication tests

- Gear train spin-down friction checks

- Balance wheel stability evaluation

These steps ensure the movement architecture mirrors genuine Rolex engineering before full regulation even begins.

Multi-Position Regulation: The Core of Accuracy

Like authentic Rolex calibers, Noob’s movements undergo six-position regulation, simulating how a watch behaves on the wrist throughout the day.

The movement is tested in the following positions:

- Dial up

- Dial down

- Crown up

- Crown down

- Crown left

- Crown right

This allows technicians to fine-tune amplitude and beat error using micro-adjustments on the balance wheel, ensuring stable accuracy whether the wearer is typing, walking, or resting.

A properly regulated Noob movement targets:

- +/- 8 seconds per day accuracy

- Full amplitude above 270°

- Beat error below 0.3 ms

These numbers closely mirror Swiss COSC expectations — a standard rarely seen in lesser replicas.

Shock & Vibration Testing: Real-World Durability

A critical part of Noob’s revival has been its investment in shock-absorption simulation. Using equipment modeled after Swiss testing rigs, each batch of movements undergoes vibration patterns designed to mimic:

- Sudden wrist turns

- Accidental knocks

- Daily micro-impacts during movement

The goal is to ensure the Parachrom-style hairspring clone, KIF-style shock absorber, and jewel bearings can withstand everyday wear.

Movements that lose amplitude or show irregular beat patterns are rejected before assembly.

Power Reserve Verification

Noob’s clone 4130 and 3235 movements claim a 70–72 hour power reserve, similar to genuine Rolex performance. To guarantee this:

- Movements are fully wound using controlled torque.

- They are placed on automated timing racks.

- Power decay is logged electronically until full stop.

Only movements maintaining stable amplitude for the full period pass. This is why modern Noob watches can sit over a weekend without stopping — a hallmark of true super clone quality.

Temperature and Environment Simulation

Accuracy changes with temperature. To mimic real-world conditions, Noob tests movements at:

- 5°C (cold conditions)

- 20°C (room temperature)

- 40°C (warm skin contact)

These tests ensure hairspring elasticity and lubricant stability remain consistent. This improves:

- Long-term accuracy

- Chronograph reset alignment

- Power reserve behavior

- Anti-magnetic performance

Environmental chambers are also used to test humidity resilience, preventing rotor or gear train corrosion in humid climates.

Full Watch Testing After Assembly

Once the movement is cased, testing begins again — because casing tension, gasket pressure, and rotor clearance can all affect timekeeping.

Each assembled Noob Factory watch undergoes:

- 24-hour timing machine cycle

- Rotational wrist simulator testing

- Water-resistance pressure tests (up to 10 bar for Submariner models)

- Lume consistency inspection

Only watches that maintain accuracy after casing and pressure testing are released. This mirrors genuine Rolex quality control in concept and execution.

Why This Matters

The average replica watch focuses only on looks. But Noob Factory’s philosophy has always been different:

a replica should function like the original, not just imitate it.

By adopting multi-position regulation, mechanical simulation, environmental testing, and full post-assembly verification, Noob has created a standard unmatched by most factories.

This is why collectors still trust Noob Factory — because every movement is more than a copy. It’s a result of engineering discipline, data-driven testing, and a deep respect for the mechanics of Rolex.

Final Thoughts

Accuracy remains the heart of every watch, and Noob Factory’s testing philosophy proves it is more than a name in the replica world — it is a true manufacturer with technical depth. Through science-based regulation and rigorous quality control, Noob delivers super clone movements that perform with confidence, stability, and mechanical integrity.

In the field of replica Rolex engineering, Noob continues to set the benchmark for how a watch should tick.